According to Alex Berdin, this innovative technology is essentially like a printer for flat optics, offering unprecedented control and versatility in creating optical components.

Berdin’s research leverages a digital holographic microscope (DHM) integrated with a laser interference system, uniquely capable of patterning photochromic materials with unprecedented precision. This process, utilizing the light-induced mass migration of azobenzene-containing molecules, enables the one-step creation of topographies in a holographic photopatterning process. The method represents a significant leap over traditional microfabrication techniques, offering a rapid and precise approach to optical component design.

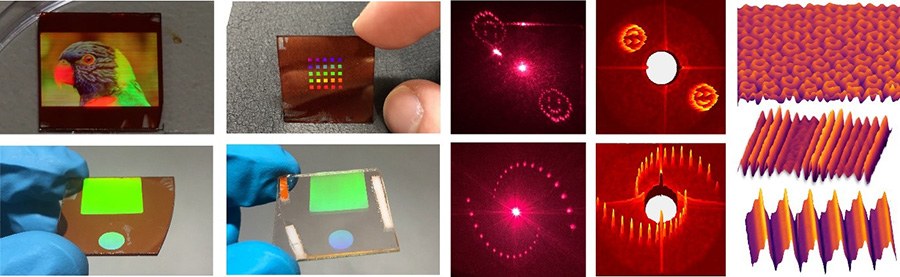

A cornerstone of Berdin's work is the ability to pattern thin films containing azobenzene molecules with DHM by superimposing surface relief gratings (SRGs). This intricate process, involving computer-controlled tuning of interference conditions and spatial scanning, enables the creation of large areas with custom topographic structures.

“These light-configurable topographies have far-reaching implications, from developing new metamaterials to improving waveguide couplers in near-eye displays,” Berdin notes.

Among the key achievements of Berdin's research is the development of a true-color hologram. It was accomplished by intricately combining SRGs with different periods to diffract primary colors, allowing for additive color mixing.

"The process involves stitching these topographies pixel by pixel based on a reference image, similar to how a printer lays down ink, but for optical elements," Berdin explains.

Berdin’s breakthrough research means not just an advancement in the field of optics, but a transformative step towards the miniaturization and enhancement of optical devices. His work is expected to have a substantial impact across various applications, from advanced imaging systems to innovative display technologies. His method stands as a testament to innovative thinking in optics.

Commercializing research results into industrial applications

Currently, Alex Berdin is leading the commercialization of his research through a project called HOLOSHAPE, funded by the European Research Council’s Proof-of-Concept grant. It aims to provide an essential manufacturing tool for companies in fields such as augmented reality.

“My method is extremely beneficial for the production of compact waveguide couplers tailored to AR applications and represents a significant advance in the miniaturization and performance enhancement of near-eye displays,” he says.

Berdin presumes this initiative is a crucial step in transforming academic research into viable industrial applications and could transform the manufacturing of optical elements.

Alex Berdin completed his Bachelor of Science and Master of Science degrees at the University of Potsdam in Germany. After working as a research assistant at the Fraunhofer Institute for Applied Polymer Research, he began his doctoral research in the Smart Photonic Materials group under the supervision of Professor Arri Priimägi. Alongside his research, Berdin has completed training in the commercialization of research results, which he will continue after completing his Doctor of Science in Technology degree.

Public defence on Friday 19 April

Alex Berdin's doctoral dissertation titled “Holographic Recording on Azobenzene Films: A Digital Holographic Microscopy Approach” will be publicly examined in the Faculty of Engineering and Natural Sciences at Tampere University on April 19 at 12:00, at auditorium Pieni Sali 1 (FA032) of the Festia building (Korkeakoulunkatu 8, Tampere). The examination will also be available for remote viewing via live stream. The Opponent will be Prof. Dr. Svetlana Santer from University of Potsdam. The Custos will be Prof. Arri Priimägi from the Faculty of Engineering and Natural Sciences.