Research focuses on coatings and surface treatments with high properties and performances. Coating development together with their manufacturing are key research areas. Thermal spray processing includes cold spraying, flame spraying, high-velocity oxygen/air fuel spraying (HVOF/HVAF), plasma and arc spraying.

Research interests include the development of coatings for harsh conditions such as icing, corrosion and wear as well as additive manufacturing by using cold spraying. We are developing future coatings by starting from material optimization through coating processing to final performance towards more sustainable future.

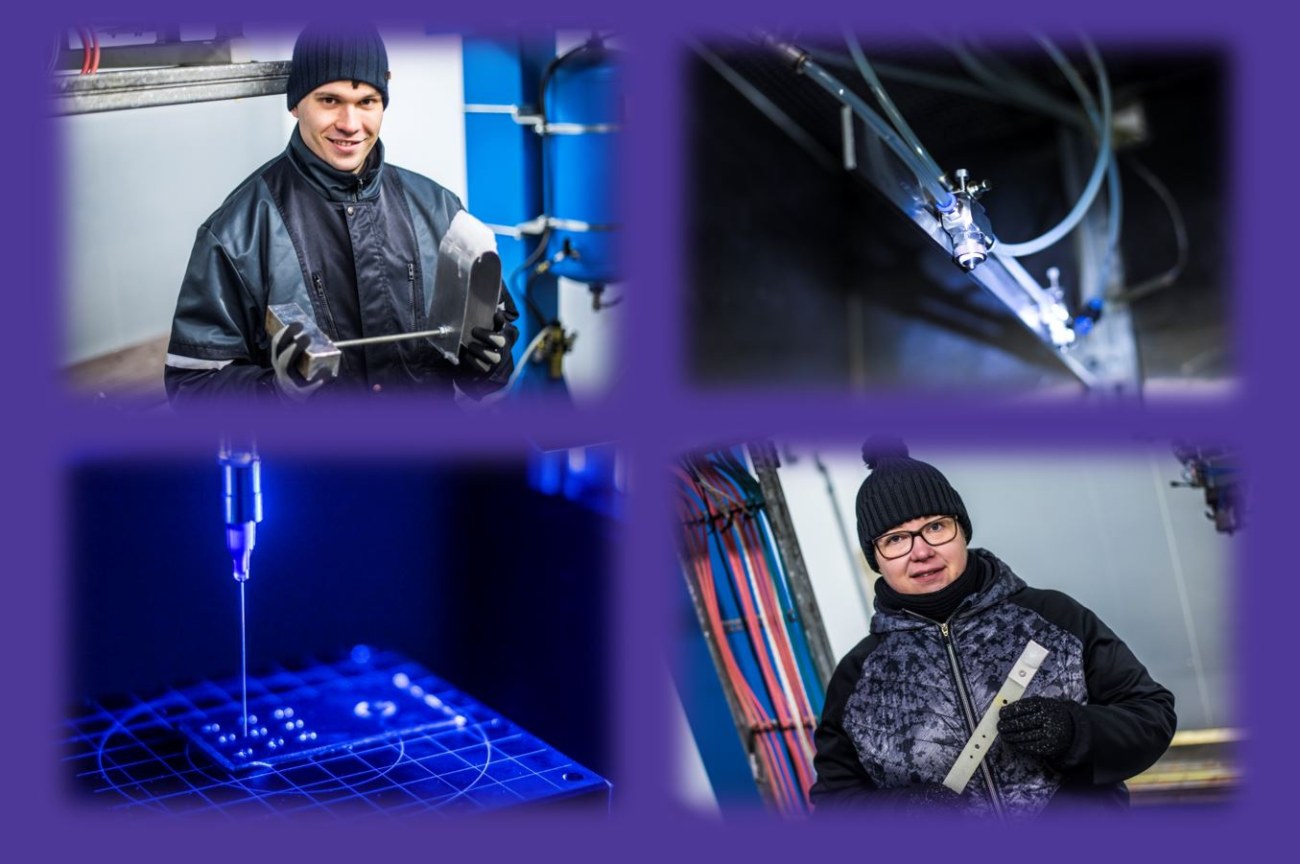

Icing Research

The research focuses on icing and its challenges, solutions and understanding of influencing factors. Our main aim is to deep knowledge of icing, find solutions to the challenges and this way, increase performance, safety, usability, cost and energy efficiency. We develop icephobic surfaces and coatings, test icing behaviour and develop testing environment to fulfil the application-related requirements. Also, our research utilizes icing simulation, supporting experimental research. Our research connects material science, surface engineering and icing aspects in order to develop durable future icephobic solutions faced in harsh arctic conditions and environments. Also, we exploit our surface engineering knowledge for developing solutions in other harsh applications, considering reusability, recycling and repairing.

Research interests include the development of icephobic surfaces and coatings, ice accretion and understanding of icing behaviour. The focus point is to study surface properties by utilizing the icing wind tunnel (IWiT) and the centrifugal ice adhesion tester (CAT) together with other surface properties and performances. Coating development is focused on thermally and cold sprayed coatings and material development.

Leader