Printed electronics infrastructure

Equipment

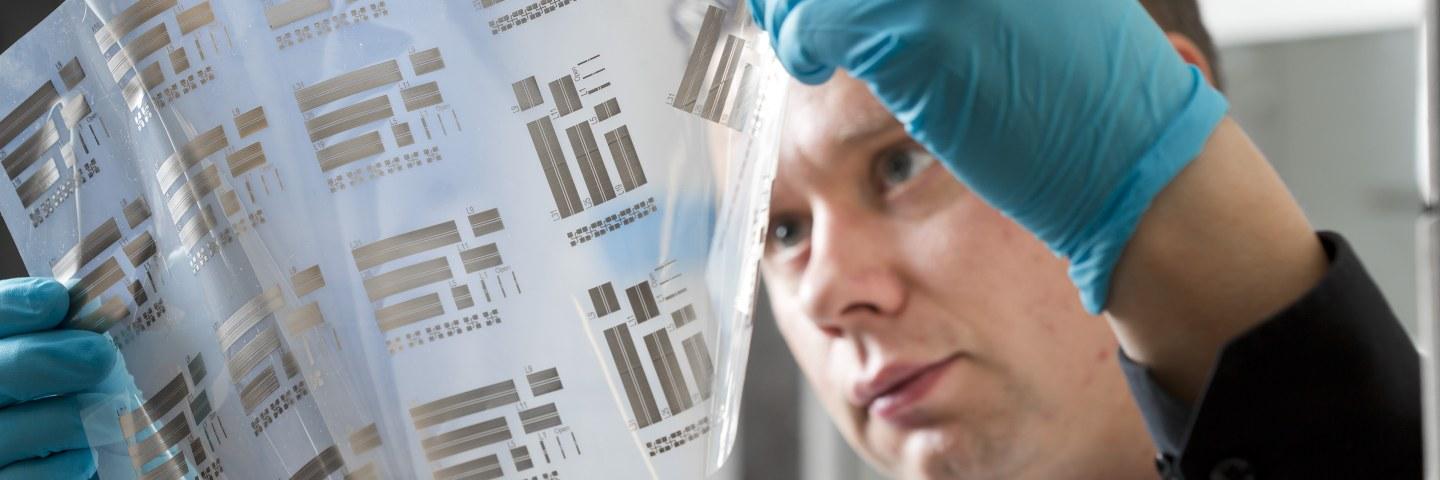

Laboratory for Future Electronics (LFE) provides the primary research environment and infrastructure for carrying out research with printed electronics, thin film electronics, energy harvesting and storage as well as hybrid electronics. LFE has over 250 m2 dedicated lab space, which includes 60 m2 dust-free processing laboratory.

LFE’s state of the art printing facility includes inkjet printers (CeraPrinter F-Serie, Super-fine Inkjet printer, two Dimatix printers, one inside a nitrogen filled glove box and one in clean room), gravure, flexo, rotary screen and dry or wet lamination (Schläfli Challenger 174), screen printers and a plasma printer for high resolution surface energy patterning.

A glove box system filled with nitrogen can be used for device fabricating and characterization. The system includes integrated Dimatix inkjet printer, ALD, spin coater and vacuum hot plate as well as combined e-beam and thermal evaporator.

Equipment for electrical characterization include probe stations, semiconductor analyzer, a potentiostat and devices for measuring supercapacitors and batteries. Mechanical properties of functional materials can also be tested. Ferroelectric material and piezoelectric material testing are also available.

More detailed information on the equipment can be found here