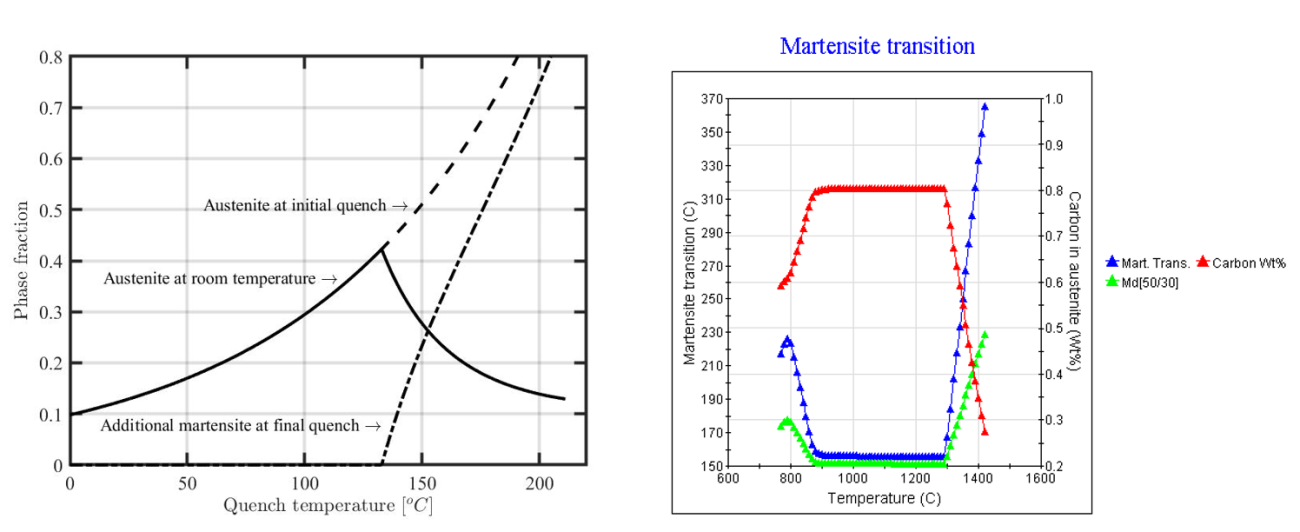

Modern steel industry has great interest in developing new advanced high-strength steels, especially for the needs of the automotive industry. The need for stronger and more ductile sheet steels has led to development of novel heat treatments such as quenching and partitioning (Q&P).

The Q&P heat treatment provides an opportunity for manufacturing new 3rd generation advanced high-strength steels. These steels can reach high strength levels without sacrificing their formability, making them a viable alternative for various engineering applications. However, there is little research conducted on the microstructure evolution of many steel alloys suitable for Q&P, and many of the mechanisms are yet to be confirmed.

The aim of this project is to investigate the mechanisms affecting the microstructure and properties of aluminum alloyed carbon steels and ferritic stainless steels during Q&P. Additionally, the project investigates the effect of carbon and chromium on the optimal Q&P-process parameters for stainless steels. The project also aims to propose new simulation models for optimizing the Q&P-process. Simulation results are validated with practical heat treatments, followed by microstructure analyses such as x-ray diffraction and electron microscopy.

Funding source

The Technology Industries of Finland Centennial Foundation, Steel and Metal Producers' Fund, research group grant.

Contact persons

Lassi Raami

Doctoral Researcher Lassi Raami

Lassi Raami