Tampere University researchers have won Grade2XL design contest on additive manufacturing

The designs were evaluated for their novelty and design purposes. The winner team was announced during the annual Meeting Materials conference on 5 April 2022, organized by Materials Innovation Institute M2i. As a prize, the Tampere University’s winning team will have their part manufactured at RAMLAB in Rotterdam.

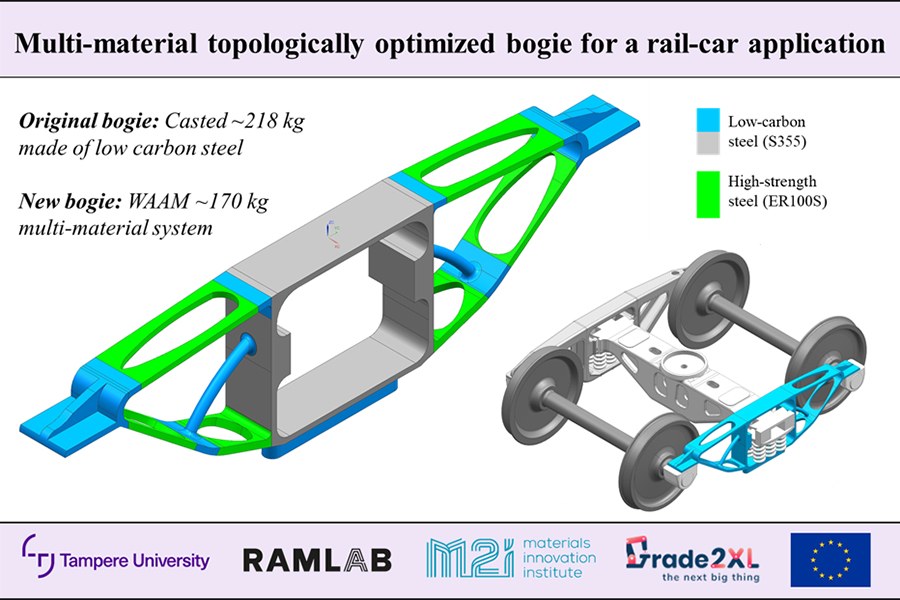

The winning design is a multi-material topologically optimized bogie for a rail-car application

Parts with an increased stiffness-to-weight ratio make wire arc additive manufacturing (WAAM) process more competitive, and higher deposition rates positively impact WAAM business cases.

The winning demonstrator is a multi-material topologically optimized structural bogie part for a railway train application.

”It’s rationale is to combine high and low strength steel and topology optimization to reduce weight hence costs of bogie production to increase the system's reparability and life. The material selection combines high-strength steel on stressed areas while keeping a low-cost, low-carbon steel (everywhere else) as the primary material,” explain Queguineur and Mokhtarian.

Antoine Queguineur recently embarked on his doctoral studies in the field of additive manufacturing. He is interested in the phenomenon affecting the final microstructure of parts manufactured with direct energy deposition processes. He has around ten years of industry experience including five years in research and development of additive manufacturing.

Hossein Mokhtarian is currently working as a university lecturer and researcher. His research interests lie in the interaction of design and manufacturing technologies and more specifically additive manufacturing. He holds a double Ph.D. degree in mechanical engineering and industrial engineering from a joint-PhD program between Université Grenoble Alpes and Tampere University.

Read the original news on M2i website.

Further information

Antoine Queguineur

antoine.queguineur [at] tuni.fi

Hossein Mokhtarian

Hossein.mokhtarian [at] tuni.fi